double side coating machine szl thermal oil radiator

- Products Details

Quick Details

-

Brand Name: OEM

Model Number: heat exchanger-531/472

Place of Origin: Jiangsu, China (Mainland)

Packaging & Delivery

- Packaging Details: Wooden packing

- Delivery Detail: 30 days

Specifications

double-side coating machine szl thermal oil radiator

Application

- Oil coolers for hydraulic systems

- Water and liquid coolers for industry and power plants

- Steam

- Unit heaters

- Fan coils

- Convectors

- Air handling units

- Ducted systems

- Cold beams

- Glycol heat recuperation circuits

- Heat pumps

- Air conditioning

- Dehumidifiers

- Close control AC

- Rooftops

- Air-handling units

- Air curtains and transportation AC

- Bottle coolers

- Chillers

- Remote condensers

- Condensing units

- Showcases

- Display cases

- Milk tanks

- Transportation AC and refrigeration

Offered Solution

- Straight or formed, L or U or O-shaped coils

- Smooth inner grooved tube or super-grooved tube with different diameters and thickness of wall

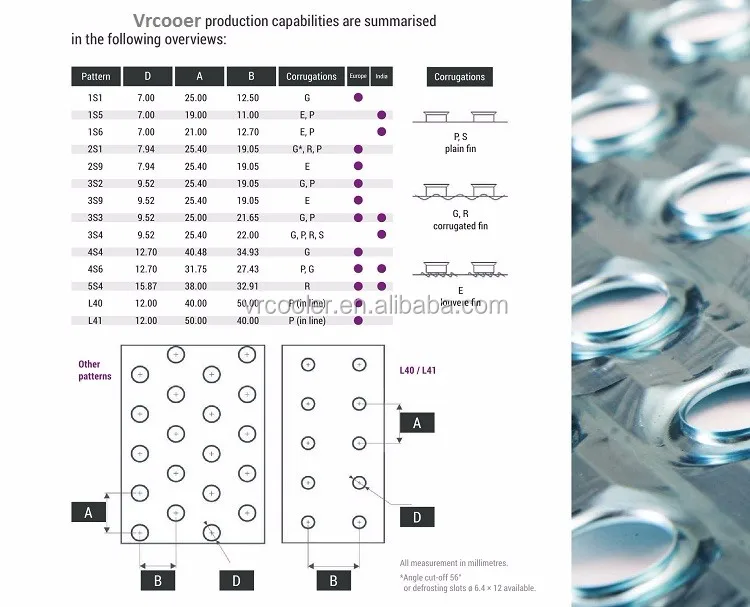

- Different approach of plain, corrugated or louvered fin profiles

- LCE Coating anti corrosion and antimicrobial protection

- High-quality powder paint

- Pre-coated epoxy (gold) or blue (hydrophilic) fin material is available

- Maximum of 10 mm fin spacing

- Defrosting slots are available in certain cases

- Coating anti corrosion and antimicrobial protection

- Pre-coated epoxy (gold) or blue (hydrophilic) fin material is available

- Circuiting for horizontal, vertical or combined use

- Circuiting with tripods and with sub-cooling sections available

Technical specification

TUBES

- Copper, Stainless steel, Aluminium, Hot dipping carbon steel, Titanium

- 5mm, 7 mm, 5/16", 3/8", 12 mm, usa market exchanger, 5/8"

- Smooth, Smooth thick-walled, Grooved, Supergrooved (deeper grooves)

- Connection to several circuits available

FINS

- Aluminium

- Hydrophilic

- Epoxy coated

- Copper

- Stainless steel

- Hot dipping carbon steel

- Titanium

CASING MATERIAL

- Thick. 1 – 3 mm

- Galvanized steel

- Aluminium

- Stainless steel

- Copper

- Brass

CASING STYLE

- End plates with or without collets

- Various design of side plates

- Fan plates (Galvanized steel and Aluminium up to 1,5 mm) with pressed collar for fan (16 possible diameters)

- Diffusers for involvement in pipeline

Lead Time: 20 - 40 days

Payment Terms: 30% T/T payment in advance, 70% T/T payment before delivery

Packing Condition: Standard export packing or customized packaging

Scale: 11 - 50 People

Country/Region: China (Mainland)/Asia

Established:

US 15-5000 / Unit 20 Unit/Units (Min.Order)

US 21-200 / Unit 20 Unit/Units (Min.Order)

US 25-2000 / Unit 20 Unit/Units (Min.Order)

US 60.00 / Unit 5 Units (1 lot) (Min.Order)

US 20-2000 / Unit 2 Unit/Units (Min.Order)